Highly customized

Whether it is wall panels or floors, we can customize production according to your unique style and build an exclusive environmental aesthetic space for you in an efficient and fast way.

Pay attention to quality

We strictly control the process and quality throughout the entire process, meticulously craft each procedure, and track logistics and transportation in real time to provide you with high-quality products and considerate services.

Fast support

We have a team of senior design and construction experts. No matter what problems you encounter in the design or construction process, we can respond and answer them quickly and provide considerate and professional guidance throughout the process.

Hot-selling product recommendations

Based on the in-depth insight into product sales data and the precise analysis of market feedback, we carefully select and recommend the following high-potential products that have been verified by the market. With their outstanding market performance and consumer recognition, these products can help you quickly connect with the target audience, effectively shorten the product testing cycle in the market, accelerate the commercial layout process, and allow you to seize the initiative in the competition, reduce the cost of trial and error, and efficiently start the journey of market expansion.

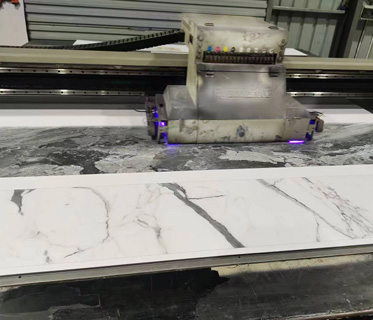

Production process display

The wall panel production process covers multiple precision processes: first, the raw materials are subjected to high-pressure forming through hydraulic equipment to ensure that the board structure is dense; then they are accurately cut according to specifications by CNC cutting machines, and the dimensional tolerances are calibrated simultaneously; then they enter the polishing process, and the surface burrs are eliminated by grinding equipment to improve the flatness; then they are evenly coated with environmentally friendly paint through the spray line, and the coating thickness and adhesion are strictly controlled; then the edge inspection process (calibrating the contour accuracy with the reference edge) and the grooving operation (reserving pipeline grooves or splicing tenons according to the design) are completed in turn, and professional equipment is used to ensure position accuracy; finally, dust-proof and moisture-proof packaging is carried out, and the first-piece inspection and process sampling are carried out throughout the process to ensure that the quality of each link is controllable, so as to achieve high precision and stability of the finished product.

Spraying process

Using high-precision UV digital printing technology, wall panels can be customized with diverse styles of patterns, texts and artistic patterns. Under 2880dpi high-definition output, the brushstrokes are lifelike and delicate, and some processes can present a three-dimensional relief touch, seamlessly adapting to neo-classical, Italian light luxury, new Chinese and other design languages, making the wall a customizable art carrier.

Border patrol process

Through CNC milling machines, milling and grinding are performed along the contour using a milling cutter. Before processing, the reference edge must be accurately positioned, the feed speed and cutting depth must be set, and the trajectory must be calibrated in real time during processing to ensure edge dimensional accuracy (within a tolerance of ±0.05mm) and surface roughness, ensure contour consistency, and improve sheet assembly accuracy and appearance quality.

Grooving process

Use special slotting equipment to open slots or mortises at designated locations on the wallboard according to the design drawings. First, lay out the lines to determine the slot location and size, adjust the tool depth and feed speed, and cut at a uniform speed along the marked line. The depth is usually controlled at 1/3-1/2 of the board thickness to avoid penetration damage. Check the slot width, depth, and verticality to ensure that it meets assembly requirements such as board splicing, and ensure wall flatness and installation accuracy.

Company latest news

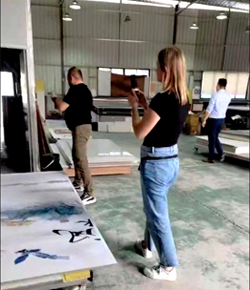

Carbon crystal panels, stone crystal panels, anti-collision panels, acrylic ice crack panels and other products are both decorative and practical due to their outstanding advantages such as exquisite patterns, environmentally friendly and durable materials, and quick installation by workers. At present, the products have been exported to many countries and regions around the world. With stable quality and excellent performance, they have attracted many foreign customers to come for field visits. Based on the high recognition and trust of the products, both parties have successively reached long-term and stable cooperative relations and continued to expand the domestic and foreign market territory.

French customer on-site inspection cooperation

Polish customers on-site inspection cooperation

Cameroon customer on-site inspection cooperation

British customer on-site inspection cooperation

Brands

We have three major brands: Mingya takes the domestic diversified distribution network as the core, providing a wide range of products to agents, covering the needs of multiple fields such as home furnishings and building materials; Belle focuses on large domestic design and decoration companies, and takes high-end decoration styles as the orientation, providing integrated services from scheme design to product customization, accurately matching high-end scene needs; Yipin is deeply involved in the international market, taking overseas trend elements as the design origin, focusing on the research and development of products that meet global aesthetic trends, and mainly exports to overseas markets such as Europe, America, and Southeast Asia. The three major brands have formed a diversified business structure with domestic distribution, high-end customization and international markets in parallel.